Machining Ability of each Factory

| Deep Hole Drilling Capability List | |||

| Factory | KAWASAKI | HIROSHIMA | KYUSHU |

| Inner Dia. mm |

3 to 400 | 4 to 750 |

11.2 to 450 |

| Length mm |

200〜6,000 (9,000) |

200〜6,200 (10,000) |

150〜6,000 (7,500) |

| Number of BTA System Machines |

8 | 4 | 4 |

| Number of General-purpose lathes |

5 | 6 | 3 |

| Number of NC lathes |

0 | 0 | 1 Mazak j-400 |

| Number of Honing |

1 | 3 | 1 |

| Crane (Max. load Ton) |

10 | 15 | 15 |

What is Deep Hole Drilling Machine?

We will process the deep drilling hole exceeding 400 mm from small diameter using BTA System deep hole drilling machine manufactured by ourselves in-house. Machines that support precision, reliability and experienced operators with extensive experience will respond to all processing needs.

Lathes and honing machines are also working in conjunction with deep hole drilling machines. In addition to deep hole drilling processing of BTA System, we will support preparation of materials, heat treatment, various lathe machining, and honing in total. Please consult to sales person at each factory.

━━━Processing experience

Processed item

· Steel & Cast steel related products: various rolls, shaft parts, molde

· Industrial machine parts: various shafts, cylinders, screws

· Drilling related parts: Tool joint, ground pipe for burying sensors

· Communication related parts: Cases for submarine cables and earthquake sensors

· Nuclear power generation related: rod parts for CRD and ICM, etc.

· Shipbuilding related: connecting pipe, manifold block, various cylinders

Introducing of the products processed

· SUS316 φ245/155×φ123/102×5,000L

· S45C φ340/φ190×4,000L

· Copper alloy φ175 / φ125 × 3,000 L

· SACM645 φ140 / φ 56 x 2, 100 L

· Inconel 750 φ 200 / φ 150 x 1, 700 L

· Hastelloy φ 353/318 × 1,800 L

· CF 34 φ 105 × φ 59 × 1, 500 L

・Ti64 φ100×φ65×700L

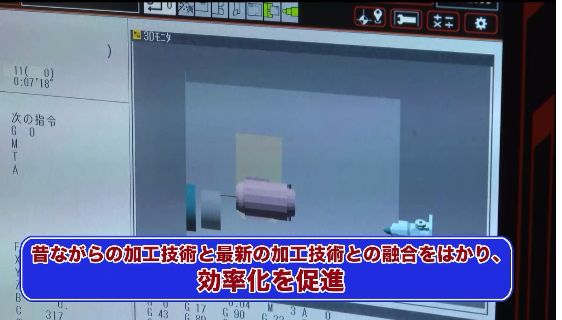

━━━MAZAK J-400

Mazak's INTEGREX J-400 CNC Multi-Tasking Machine is

Installed in Kushu Factory

MACHINE SPECIFICATIONS

| Specification | BED LENGTH - 47.2 IN / 1200 MM CapacityMaximum Swing - 25.20 in / 640 mm Maximum Machining Diameter - 19.690 in / 500 mm Bar Work Capacity - 4.0 in / 102 mm Maximum Machining Length - 45.870 in / 1166 mm |

|---|---|

| Main Spindle | Chuck Size - 12 in / 304 mm |

| Feed Axes | Travel (X Axis) - 24.21 in / 615 mm Travel (Y Axis) - 10.24 in / 260 mm Travel (Z Axis) - 48.46 in / 1231 mm Travel (W Axis) - 24.88 in / 632 mm |